Extrusion Die

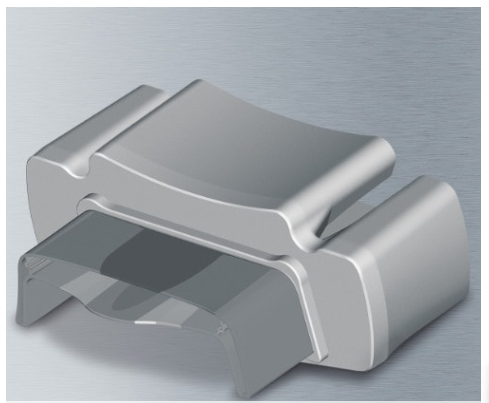

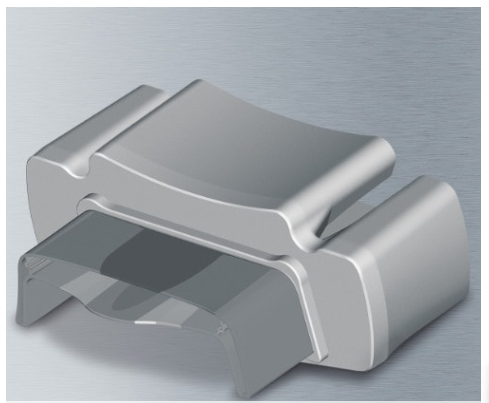

CED® Cartridge® Dies

Greater dimensional stability. High Productivity. Low Maintenance.

WEFA’s coated extrusion dies have superior durability because the bearing channel is protected from wear and tear. With our own patented coating technology, we have achieved high-level form and dimensional stability for the pressed profiles. The dies are nearly maintenance-free due to the fact that no nitriding and repolishing is required.

Without the need for nitriding cycles in coated dies, the extrusion process can be carried out with fewer interruptions. In addition, it is possible to increase the extrusion speed due to lower friction and reduced exit temperatures. These features allow you to increase the productivity of the extrusion factory.

CED® Cartridge® Dies

CED® Flat- & Porthole Extrusion Dies

CED® Insert Dies

Extrusion Dies

Maximum processing speeds. Minimal test pressings with high reproducibility.

If you’re looking for ambitious aluminum profiles, you’ve come to the right place. This is where WEFA’s specialists really shine. Together with our international extrusion plant partners, we implement innovative die concepts - always taking the latest research in flow technology into consideration. The goals are clearly defined: achieving maximum extrusion speed, reducing the number of test pressings – and all at the highest levels of reproducibility. WEFA’s flat, porthole and tube dies are used for profile applications in mechanical engineering, construction and electrical engineering as well as in the automotive industry.

We achieve outstanding results using high-quality steels in combination with our excellent design know-how and modern precision manufacturing facilities.

Whether producing large flat dies with a diameter of up to 600 mm or tackling requests for the smallest tolerances and high-quality profile surfaces – WEFA provides technically and economically-convincing solutions in premium quality.

Cartridge® Dies

Flat & Porthole Extrusion Dies

Tube Dies

Areas of Use and R&D

WEFA’s top-of-the line dies make life easier

Since its founding in 1972, WEFA’s goal has been to produce the highest quality dies that require the least amount of maintenance in the extrusion plant. The company has many years of experience with 3D design, uses only the best steels, and works with modern simulation tools and a cutting-edge machine park based on 5-axis technology. All of this enables WEFA to continually manufacture exceptional dies that require very few press samples.

Areas of Use

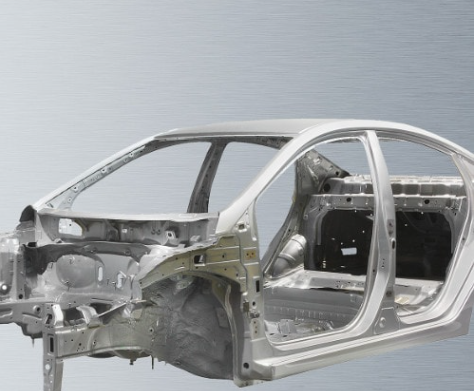

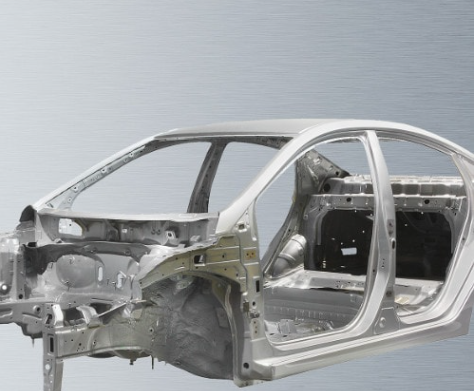

Automotive Industry

WEFA’s dies are implemented for profiles with the highest requirements for precision, surfaces, and the smallest dimensions and tolerances. Our dies fulfil the strict specifications in the automotive industry. The wide range of applications include the following profiles: trims, roof rails, heat exchangers, pipes, battery radiators, bumpers, engine parts and chassis structural components. Whatever your need may be, WEFA is your go-to partner.

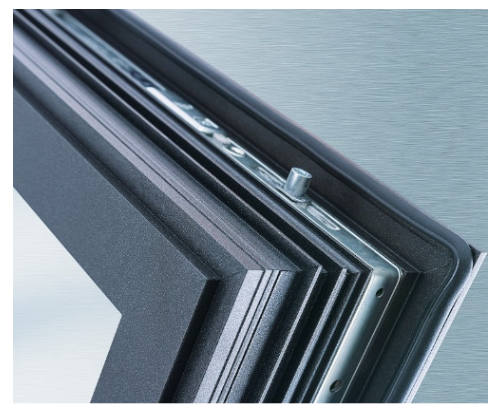

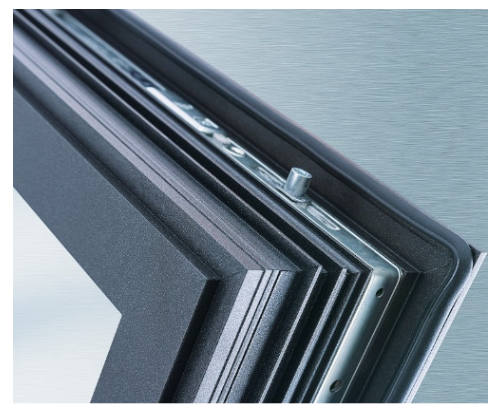

Construction Industry

WEFA has extensive experience working together with the construction industry. Numerous customers have benefitted from our expertise to produce profiles for building facades, interiors, shutters, gates, windows, doors, and much more. In addition to top designs, this sector demands quality, flexibility, and short delivery times. These are WEFA’s strengths.

Aviation Industry

The aviation industry requires are highest levels of precision and durability. WEFA dies are used in this sector to produce seamless and low corrosion tubes, as well as many other structural components. Our coating technology is in a class by itself and has become an integral facet in this industry.

Industrial Profiles and Electrical Engineering

There is also a strong demand for WEFA’s dies in the electrical engineering industry and a wide range of other applications, such as: tent poles, ice machines, coffee machines or entertainment media. WEFA prides itself on being able to find solutions for the most complex structures and requirements of our customers’ development engineers.

Areas of Use, R&D and Innovation

WEFA has set an ambitious goal of making our customers’ visions economically feasible and thereby be able to expand both their and our own market potential. The resulting business success, stemming from the work of our internal R&D department as well as the long-term partnerships with universities and research centers, is complemented by our joint development collaborations with our customers.

This has led to our consistently developing innovative products and services. WEFA’s R&D focus is on recognizing development trends and finding the appropriate solutions for our customers. This resulted in the development of new products and services in the area of extrusion, the company’s historical expertise, but also in the area of coating technology, various other die technologies, as well as for medical technology applications. These breakthroughs have been accompanied by integrating innovative digitalization technologies, used for both simulation and design technology as well as for internal automation technology.

Medtec

Medtec is one of our company’s innovative business areas:

WEFA is a series-A investor in the Konstanz company stimOS GmbH, an ISO 13485:2016 certified medical technology company. StimOS develops innovative procedures for the refinement, functionalization and activation of implant materials. StimOS is a service provider that makes this technology available for implant manufacturers. They have a partnership with the company, SpineFuseMBT, which develops implants for spinal surgery and other body parts, and offer services in the area of product development and approvals.

Partners

WEFA has partnerships with all relevant universities, research groups and organizations working in the area of aluminum extrusion. The company is involved in numerous projects with different emphases in order to develop and implement the latest, future-oriented technologies. WEFA is currently working together with the ETH in Zurich and its Institute for Virtual Production, the Forschungszentrum Strangpressen at the TU Berlin, the TU Dortmund, the University of Hannover, the Konstanz University of Applied Sciences, Ohio University, and the German Society for Material Sciences.